How to Select the Right Floor Grinder, Tooling, and Accessories

Luke Harrison2025-04-23T20:46:23+01:00(And Why Dust Control Should Be Your Top Priority)

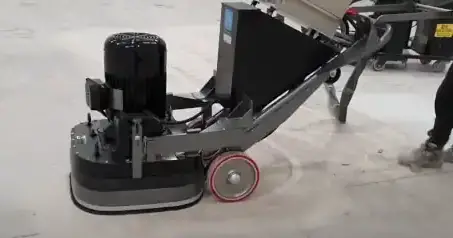

Whether you’re prepping a residential garage or a commercial warehouse, using the right floor grinding setup is essential. From machine size to power source, tooling selection to dust control, each piece of the puzzle affects efficiency, finish quality, and safety. In this guide, we break down how to choose the right grinder, tooling, and accessories — and why using the correct dust extraction system could save your health and your wallet.

Step 1: Choosing the Right Floor Grinder

Grinder Types:

- Single-Disc Grinders – Great for small or light-duty jobs.

- Dual-Disc Grinders – Cover more ground with consistent pressure.

- Planetary Grinders – Ideal for polishing and medium-to-heavy prep work.

- Ride-On Grinders – Built for large industrial or commercial spaces.

But before you pick the type, consider your available power source.

View our full range of floor grinders here!

110V vs. 415V Floor Grinders

Understanding voltage is key to selecting the right machine for the job site.

⚡ 110V Grinders

- Common Use: Small grinders on residential or light commercial sites.

- Pros:

- Plug into standard site transformers.

- Safer for indoor work and sites with limited power.

- Lightweight and portable.

- Cons:

- Limited power output.

- Suitable for light-duty grinding only.

- Slower removal rate.

⚡ 415V Grinders (Three-Phase)

- Common Use: Medium to large commercial/industrial sites.

- Pros:

- Higher torque and speed = better performance on harder concrete or coatings.

- Handles heavier tooling and wider working widths.

- Efficient for large-scale removal and polishing.

- Cons:

- Requires three-phase power (not always available on-site).

- Heavier and less portable.

⚠️ Tip: Always confirm power availability before selecting a machine. Running a high-powered grinder on the wrong power source can trip breakers, damage equipment, or cause delays.

Step 2: Selecting the Right Tooling

Tooling is where performance meets the surface. Choose based on what you’re grinding or removing:

- Metal Bond Diamonds – Tough, aggressive grinding (ideal for hard concrete).

- Resin Bond Diamonds – Fine grinding and polishing stages.

- PCD (Polycrystalline Diamond) – Removes coatings like epoxy or paint fast.

Consider:

- Bond Hardness: Soft bond for hard concrete; hard bond for soft concrete.

- Grit Size:

- Coarse (6–30 grit) = heavy removal.

- Medium (40–80 grit) = blending and smoothing.

- Fine (100–3000+ grit) = polishing stages.

- Segment Shape: The more segments, the smoother the finish (but slower removal).

🧱 Concrete Hardness vs. Tool Bond

Concrete varies in hardness — usually measured with a Mohs or rebound test — and the diamond bond needs to match that.

| Concrete Type | Bond Type to Use | Why? |

| Hard Concrete (e.g., newer slabs, high PSI) | Soft Bond | Exposes diamonds faster to stay aggressive on hard surfaces. |

| Medium Concrete (most general slabs) | Medium Bond | Balanced wear and cutting speed. Good all-rounder. |

| Soft Concrete (low PSI, dusty or porous) | Hard Bond | Prevents diamonds from wearing too quickly on soft surfaces. |

View the full range of diamonds here!

Step 3: Must-Have Accessories

- Edge Grinders – For detailed work along walls.

- Extra Weights – Add grinding pressure for tough jobs.

- Velcro Backing Plates – Quick tool changes.

- Scrapers or Shrouds – Help with coating removal and dust control.

Step 4: Dust Control – Don’t Grind Without It

Grinding concrete creates fine silica dust, a highly dangerous material that’s invisible to the naked eye. This is where a professional dust extraction system becomes non-negotiable.

Why It Matters:

- Health Risk: Silica dust causes silicosis, lung cancer, and other chronic diseases. Even minimal exposure is harmful.

- Legal Compliance: OSHA, HSE, and other agencies require dust control on job sites.

- Job Site Cleanliness: Keeps visibility clear and reduces cleanup time.

- Machine Longevity: Reduces wear on grinder motors and tooling.

Selecting the Right Vacuum for Your Grinder

Not all vacuums are created equal. Match your vacuum to your grinder’s size and power.

What to Look For:

- HEPA Filtration – Captures microscopic silica particles.

- High CFM + Water Lift – Strong airflow ensures effective dust capture.

- Auto Filter Cleaning – Keeps suction strong and filters unclogged.

- Dust Bin Capacity – Bigger jobs require larger or continuous bagging systems.

⚠️ Risks of Using the Wrong Vacuum:

- You risk breathing in toxic dust.

- You could violate safety regulations and face fines.

- Dust buildup can damage your grinder and tooling.

- Poor suction leads to poor grinding results and unnecessary rework.

View the full range of dust control vacuums here!

Final Checklist Before You Grind

✅ What surface am I working on?

✅ What’s the coating or finish goal?

✅ What power is available (110V or 415V)?

✅ Is my tooling matched to the surface and grinder?

✅ Do I have proper dust extraction?

✅ Am I wearing correct PPE?

Wrap-Up: Right Gear = Better Results

Whether you’re grinding off adhesive on a small concrete pad or polishing 10,000 sq ft of warehouse flooring, the right floor grinder setup makes all the difference. Don’t cut corners with tooling or dust control. The results will show — and your lungs will thank you.

Final Checklist: What You Need Before You Grind

✅ Grinder matched to power source (110V or 415V)

✅ Tooling bond matched to concrete hardness

✅ Grit size appropriate for the job stage

✅ High-quality dust extraction system

✅ PPE: Respirator, eye protection, ear protection

✅ Accessories for edge work and increased efficiency

Wrapping Up

Using the right grinder, tooling, and accessories is about more than just getting the job done — it’s about doing it efficiently, safely, and to the highest standard. Pair your setup with the proper dust control and you’ve got a winning formula for any surface prep job.

Need help choosing the right bond for your concrete? Or unsure if you should go 110V or 415V? We’ve got you covered — get in touch with our experts for personalized advice on your next project.